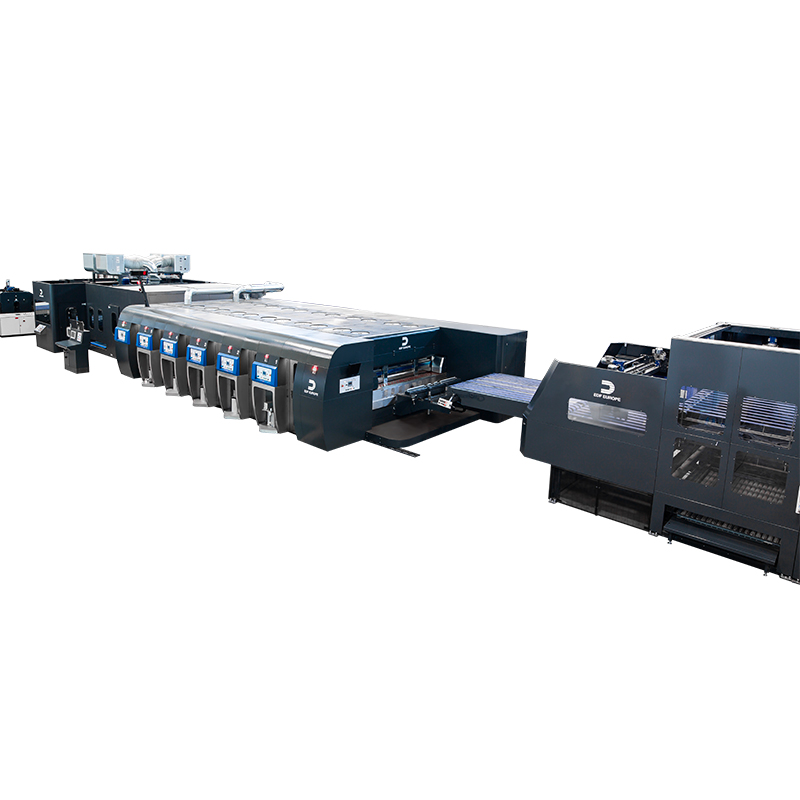

High-quality bottom-printing machines designed to allow for the quick changeover of the print modules, located outside the pit. The anilox roll can be changed up to 3 times per printing unit. The sheets are conveyed by vacuum. Productivity is up to 200 sheets per minute. A chamber for quality control and automatic ink testing is available upon request.

Archives: Prodotti

CB 08

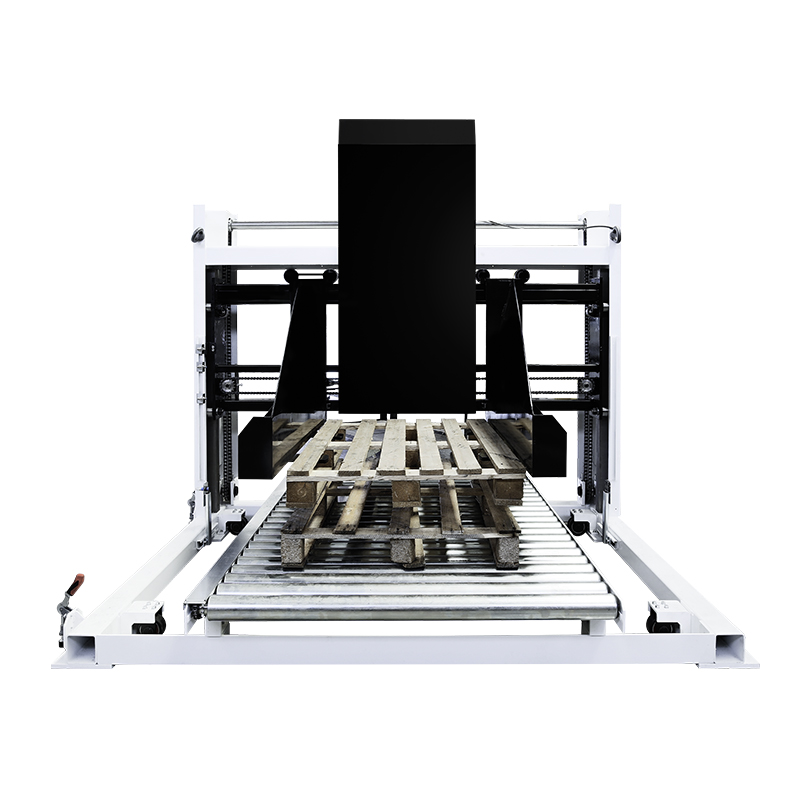

A pallet dispenser for automatically de-stacking individual pallets.

It can be installed next to palletisers with automatic feeding.

HGL 1632

High-quality bottom-printing machines that allow for the quick changeover of the print modules, located in the pit. Possibility of automatically changing the anilox roll up to 3 times per printing unit. The sheets are conveyed by vacuum. Productivity is up to 200 sheets per minute. Optional extras include a chamber for quality control and automatic ink testing.

Apstar HS

A servomotor-driven, bottom-printing machine with openable modules and a vacuum sheet conveyor.

Available modules: printer, slotter, die-cutter. Machine configurable as both a printer slotter and a casemaker (FFG).

Apstar HG2

A gear-driven, bottom-printing machine with openable modules and a vacuum sheet conveyor.

Available modules: printer, slotter, die-cutter. Machine configurable as both a printer slotter and a casemaker (FFG).

Topra GD

A gear-driven, top-printing machine with openable modules and a vacuum sheet conveyor.

Available modules: printer, slotter, die-cutter. Machine configurable as both a printer slotter and a casemaker (FFG).

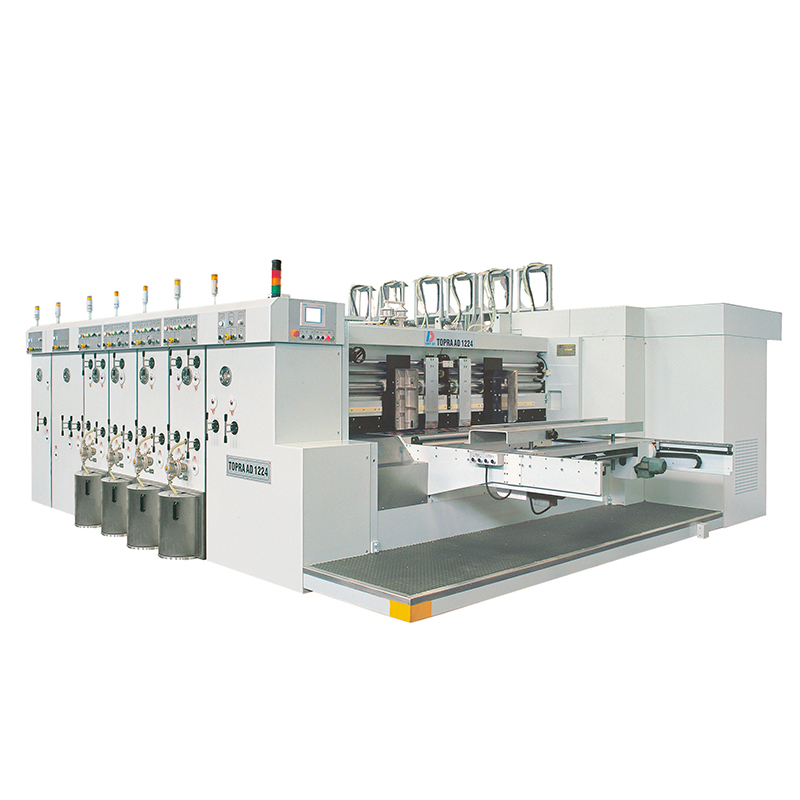

Topra AD

A gear-driven, top-printing machine with openable modules and a pulley conveyor.

Available modules: printer, slotter, die-cutter. Machine configurable as both a printer slotter and a casemaker (FFG).

Transfer

A sheet transfer unit to be installed between a modular printing line and an automatic flatbed die-cutter, designed to compensate for the difference in level between the cardboard platform of the printing machine (low) and that of the die-cutter (high).

It features software that keeps the speeds of the two connected machines synchronised, thus making them operate as a single line.

Flexystack IF

A stacker designed for installation at the flexographic printing machines’ outputs.

Ensures optimal stacking with shingled sheet conveying.

Stack changeover takes place with zero machine downtime thanks to a lance system that supports the first boxes in the new stack, thus eliminating downtime for maximum productivity.

All the components are motorised and controlled via a graphic interface, for a high level of automation with minimal errors.

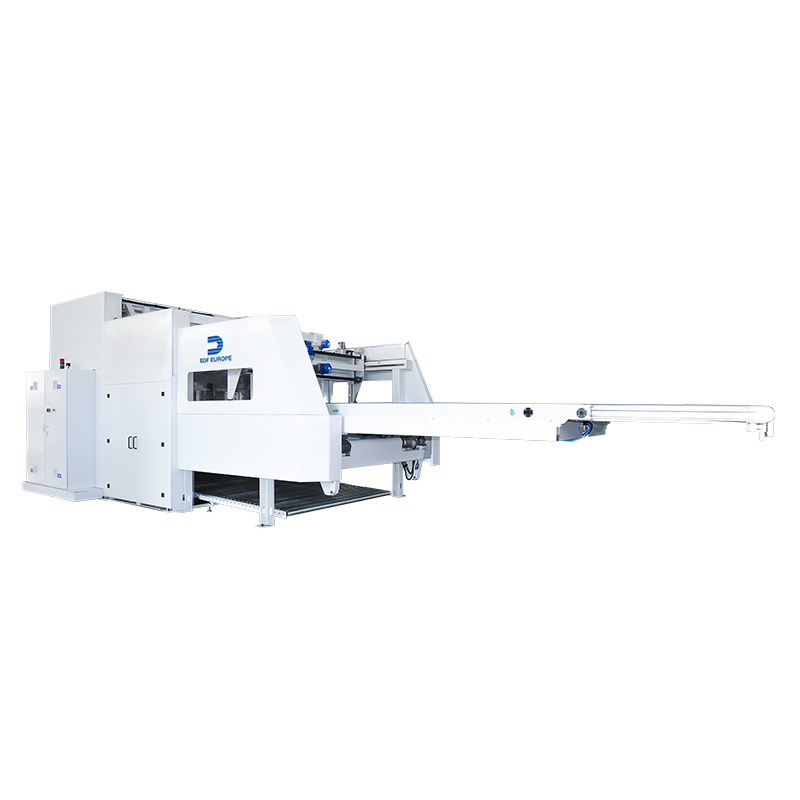

Flexyfeed 920

A high-performance mini line feeder with all the features of the Flexyfeed series, and the added possibility of integrating an ultra-high speed bundle tipper, which allows top-printing machines to be fed at extremely high speeds.

Consisting of a single module, the tipper can be removed and used to feed a bottom-printing machine as well.